Nanotec Photovoltaic-Energy panels are produced utilising functional, printable pastes based on nanoparticles with specific physical, electrochemical, and photomechanical properties that allow the generatation electrical energy from sunlight, to store this energy, to convert energy into light and heat.

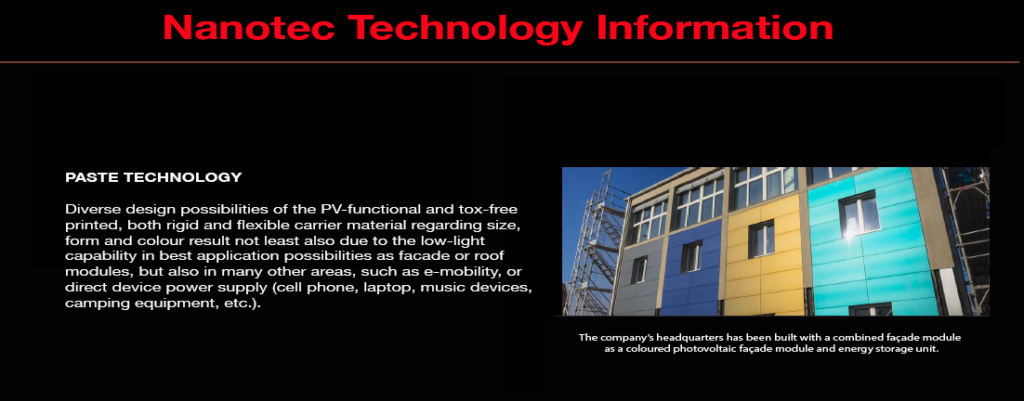

A special patented screen-printing process allows the functional pastes to be printed with high precision and homogeneously on almost any material.

The combination of the production of nanoparticles and application-specific pastes is based on specific recipes and manufacturing processes as a result of 17 years of research and development

Nano-structured layers in thin film solar cells offer three important advantages.

First, due to multiple reflections, the effective optical path for absorption is much larger than the actual film thickness.

Second, light generated electrons and holes need to travel over a much shorter path and thus recombination losses are greatly reduced. As a result, the absorber layer thickness in nano-structured solar cells can be as thin as 150 nm instead of several micrometers in the traditional thin film solar cells.

Third, the energy band gap of various layers can be made to the desired design value by varying the size of nano particles. This allows for more design flexibility in the absorber of solar cells.

The manufacturing process used allows to achieve minimized production costs for which the coatings are applied using special highly automated printing machines.

Coatings can be produced extremely efficiently in large quantities.

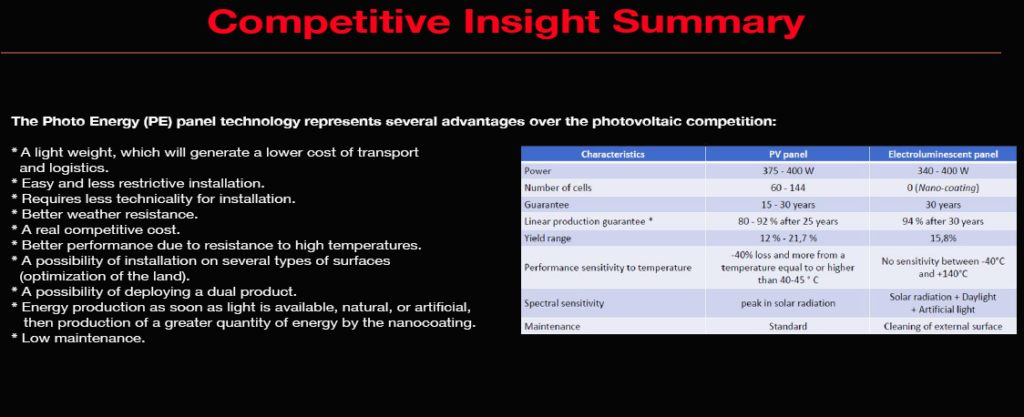

The temperature range has been successfully tested from minus 50 degrees to +150 degrees.

Inexpensive solar cells, which would utilize nanotechnology that would help preserve the environment.

Inexpensive solar cells would also help provide electricity for rural areas or third world countries.

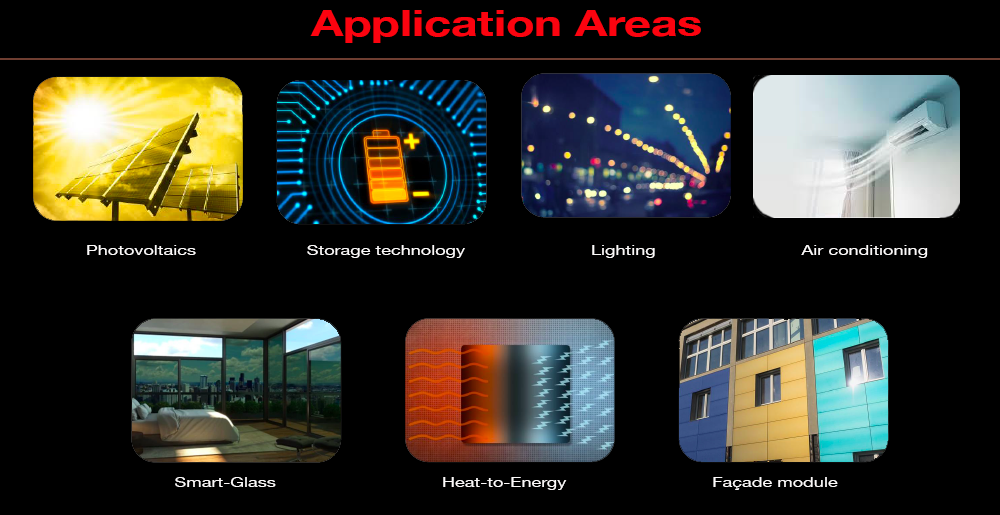

Cheap solar cell could be used for lighting, hot water, medical devices, and even cooking.

The nanotechnology materials are recyclable.

Today’s solar cells are simply not enough efficient and are too expensive to manufacture for large-scale electricity generation. However, potential advancements in nanotechnology may open the door to the production of cheaper and slightly more efficient solar cells.

The Conventional solar cells have two main drawbacks: efficiencies and their expensive manufacturing cost.

The first drawback, inefficiency, is almost unavoidable with silicon cells. This is because the incoming photons, or light, must have the right energy, called the band gap energy, to knock out an electron. If the photon has less energy than the band gap energy, then it will pass through. If it has more energy than the band gap, then that extra energy will be wasted as heat. These two effects alone account for the loss of around 70 percent of the radiation energy incident on the cell.

Nanotechnology increases the efficiency of solar cells, but the most promising application of nanotechnology is the reduction of manufacturing cost.

PVs based on CdTe, CuInGaSe (CIGS), CuInSe (CIS), and organic materials are being developed with the aim of reducing the price per watt even if that means sacrificing conversion efficiency and reliability.

Utilising nanotechnology in inexpensive solar cell would help to preserve the environment.

The coatings are printed by nano-pastes developed in a specific way, in particular the coatings allowing the production of energy and its storage which fit perfectly into the category of renewable energy solutions.

Organic photovoltaic (OPV) solar cells can be used for covering greenhouses and they can be utilised in heating and cooling systems.

COST EFFECTIVE

Thin film is a more cost-effective solution and uses a cheap support onto which the active component is applied as a thin coating. As a result, much less material is required (as low as 1% compared with wafers) and costs are decreased. Most such cells utilize amorphous silicon, which, as its name suggests, does not have a crystalline structure and consequently has a much lower efficiency (8%), however it is much cheaper to manufacture .

***

For further information or to arrange an initial meeting (in person or via Zoom) please contact:

Gianluca Di Caro

Chief Executive Officer

S.Y. Capital Holdings Limited

71-75 Shelton Street,

Covent Garden,

London WC2H 9JQ,

United Kingdom

Mobile/WhatsApp/BOTIM (UK): +44 (0)7789 364702

Phone: +44 (0)20 8202 8224

Mobile/WhatsApp/BOTIM (Saudi Arabia) +966 56 674 0363

E.Mail: gianluca@sycapital.uk

E.Mail: info@sycapital.uk

Web: www.sycapital.uk